Permanent Magnets Dominate EV

Vehicle electrification is a growing market for rare earth magnets. Consumption of rare earth magnets in transportation is estimated to rise from 7,000 tons in 2015 to 17,000 tons in 2020. Government mandates to reduce pollution, as well as high gasoline prices, are driving users to purchase more environmentally friendly vehicles. Permanent magnet machines are currently the leading choice for high performance automotive applications. The rotor’s well-balanced magnetic field and the lower stator current requirement, paired with very strong positional control, result in a higher motor efficiency. Two common choices for electric vehicle applications are neodymium magnets and samarium cobalt magnets, and each has its advantages.

SmCo vs. Neo: Which Performs Better?

Temperature Considerations

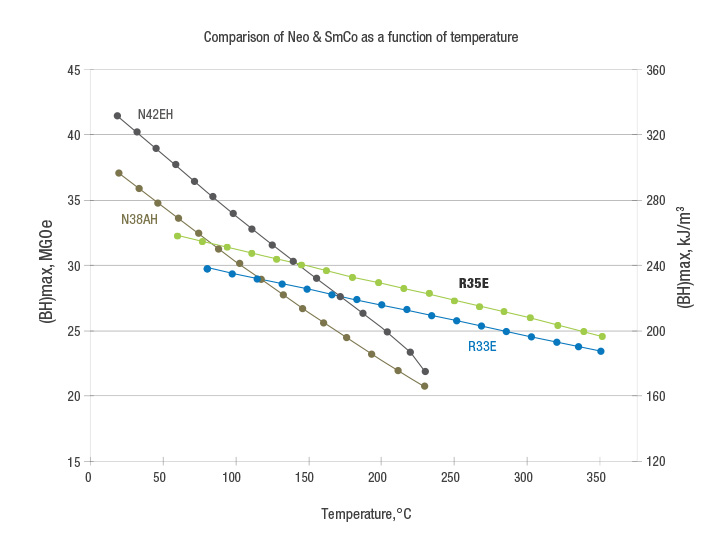

The decision between SmCo and Neo magnets often comes down to temperature. The elevated temperatures of a vehicle drivetrain require magnets that can resist demagnetization. In most cases, this necessitates the use of samarium cobalt magnets. The thermal demagnetization for SmCo magnets is much lower than for traditional neodymium-based magnets. (Consider the reversible temperature coefficient of 0.035%/C° for SmCo versus 0.10%/C° for neodymium.)

The graph below shows the remnant flux density (Br) versus temperature for different magnet materials and grades. Even though the neodymium magnet has a higher remnant flux density at room temperature, it quickly crosses the SmCo line.

A four pole motor is meant to operate inside a vehicle’s engine bay, which can have an ambient temperature from anywhere between -40°C and 125°C. This can lead to temperatures over 180°C inside the machine. Having to design around this temperature range leads to large performance differences in the magnet properties. In other words, a machine operating at room temperature will have more torque than a machine operating at 180°C for the same amount of input current.

The smaller demagnetization value of samarium cobalt magnets compared to neodymium magnets results in much flatter operating characteristics across a temperature range. Temperature stability leads to stable output performance from a four pole machine.

| Neodymium 38EH Magnets | Samarium Cobalt R35E Magnets | |

| Average torque at 20°C | 2.3Nm | 2.14Nm |

| Average torque at 180°C | 1.86Nm | 1.99Nm |

Cost Considerations

Neodymium iron boron (NdFeB) magnetic material has a high level of dysprosium, an extremely scarce and expensive rare earth element. Samarium cobalt, on the other hand, is more readily available and therefore more cost effective.

Final Decision

Despite its limitations, neodymium magnets offer the highest energy product of any material today and can be found in a wide variety of applications. When deciding whether to use Neo magnets or SmCo magnets, carefully consider the maximum temperature of the application, the required magnetic output at typical use temperature, and the total cost of the system.