High Performance Magnets and Precision Assemblies

Arnold’s high-performance permanent magnets have a wide variety of applications, from electric motors on ships, aircraft, and motorsport cars to pump couplings, batteries, solar panels and NMR Equipment. Our diverse markets allow us to keep our technologies on the leading edge of innovation.

Our custom magnet production and fabrication ensures that our Customers receive products that are specifically catered to their unique design requirements. For your R&D projects, our Technology Center is available to assist taking your project from concept to production.

Arnold Magnetic Technologies is your non-traditional trusted partner, registered with ITAR, NDAA-compliant, and able to adhere to DFARS clauses, with certifications to meet the strictest criteria.

Permanent Magnets Products

-

Samarium Cobalt Magnets

Arnold Magnetic Technologies’ industry leading RECOMA® Samarium Cobalt (SmCo) magnet materials break the performance barriers of other magnetic components. Offering several operational advantages, our top-of-the-line RECOMA 35E is currently the most power dense samarium cobalt magnet on the market, and is specifically created for the most demanding environments.

Learn More -

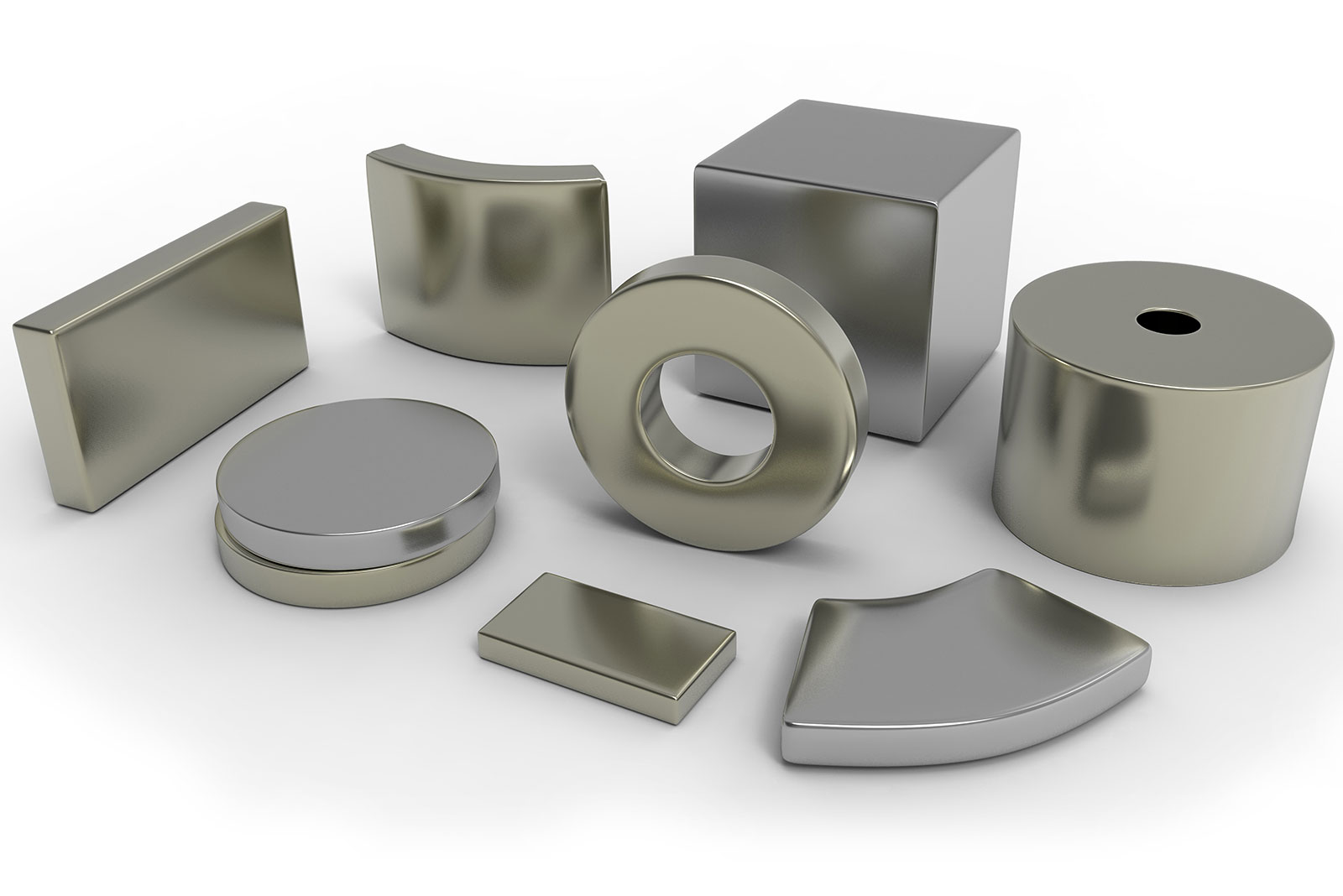

Neodymium Iron Boron Magnets

Neodymium iron boron (NdFeB), or “neo” magnets offer the highest energy product of any material today and are available in a wide range of shapes, sizes and grades including GBD. Neo magnets can be found in a variety of applications including high performance motors, brushless DC motors, magnetic separation, magnetic resonance imaging, sensors and loudspeakers.

Learn More -

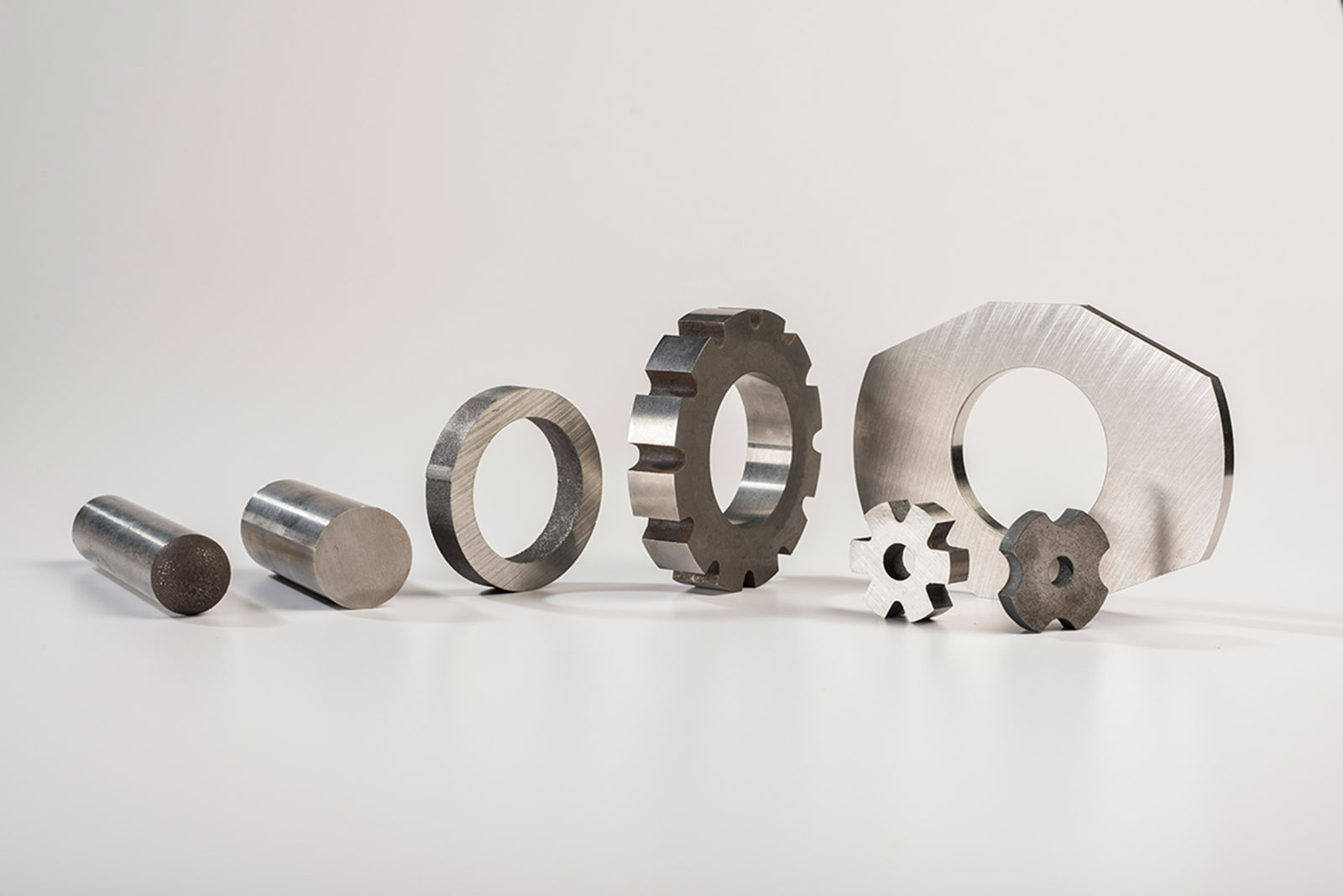

Alnico Magnets & Custom Assemblies

Alnico delivers impressive flux density at an economical price. It boasts the lowest reversible temperature coefficient of any standard commercial magnet material (0.02% per degree centigrade) allowing for excellent stability over a wide temperature range. Alnico is also inherently corrosion resistant.

Learn More -

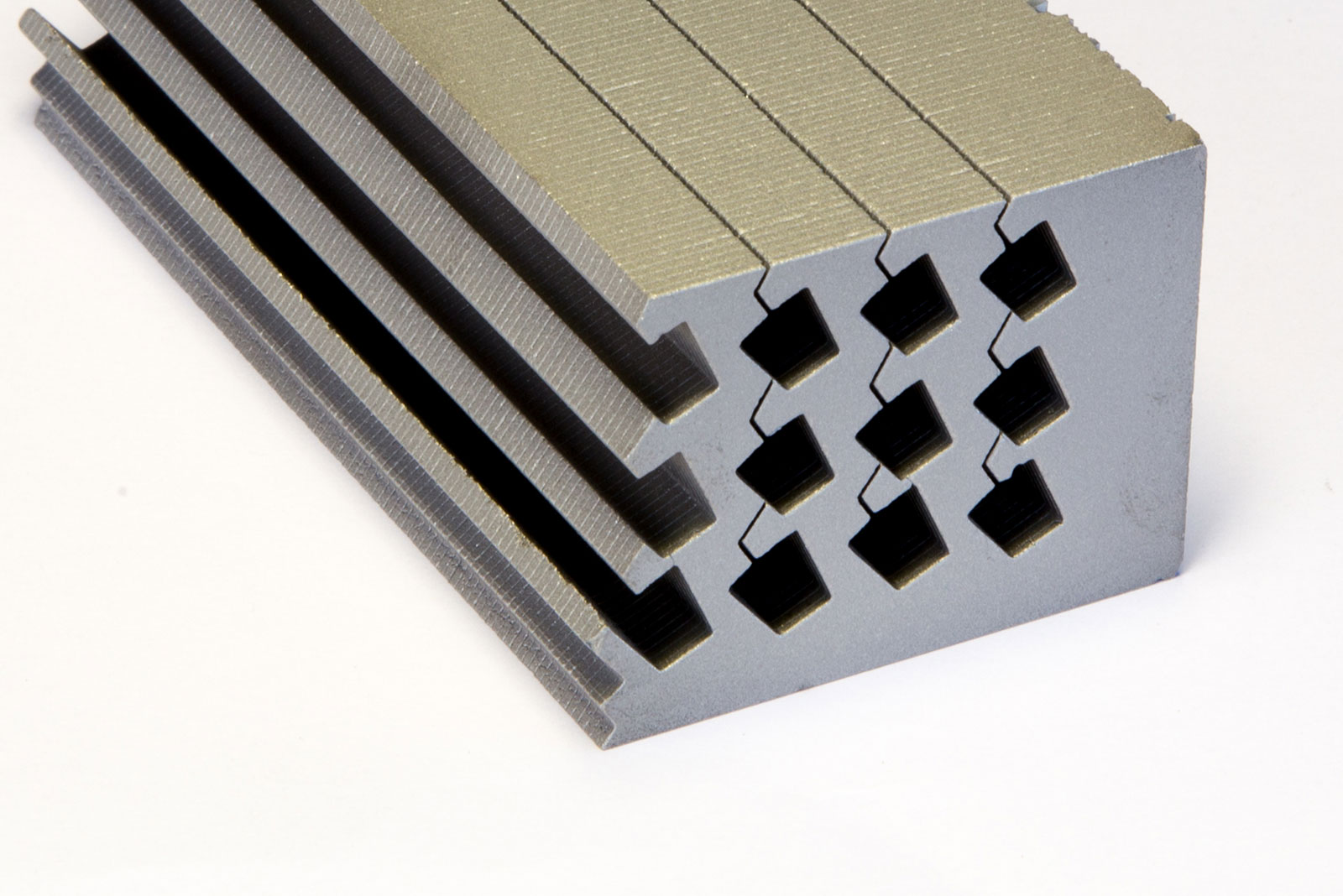

L-Type Laminated Magnets

High efficiency demands the best materials, and the Arnold L Type laminated rare earth magnets are proven to reduce eddy current losses in high efficiency motors. Less eddy current loss means less heat and less waste. Designers in the aerospace, automotive, motorsport, and industrial markets are turning to laminated rare earth magnets.

Learn More -

Injection Molded Magnets

Injection molded magnets are essentially fully dense magnetic powders blended with a variety of polymer base materials. Depending on the combination of magnetic material and polymer selected, a wide range of final material properties are possible.

Learn More -

Precision Magnetic Assemblies Manufacturing

From straight-forward to complex combinations of magnetic and non-magnetic materials, our advanced assembly services offer unparalleled expertise, quality and affordability.

Learn More -

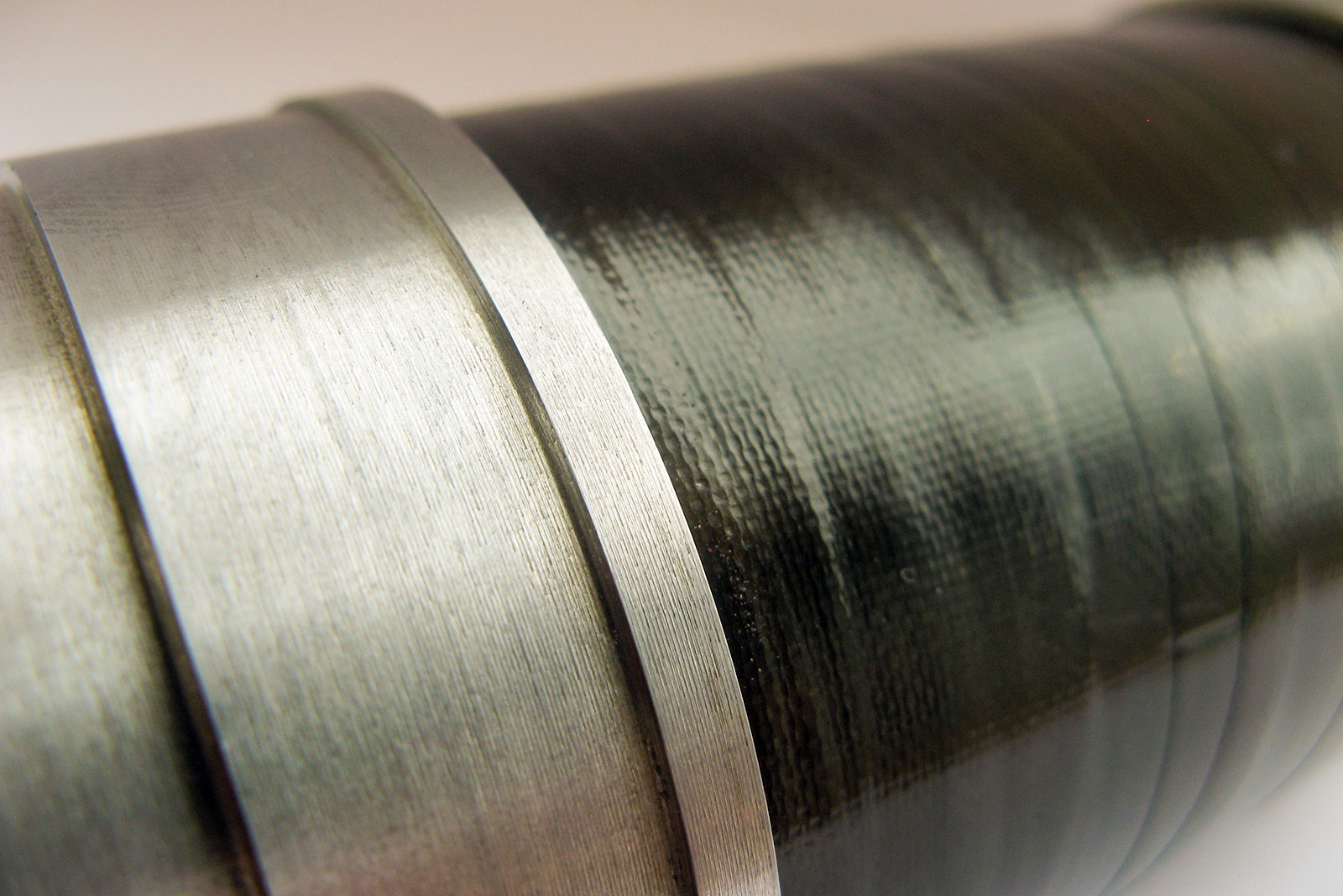

Encapsulated Magnets

Composite and metallic encapsulation solutions for a wide range of permanent magnet systems and applications. Wraptite composite sleeves offer a superior design alternative for higher performance applications in which rotational speeds exceed 50K RPM.

Learn More -

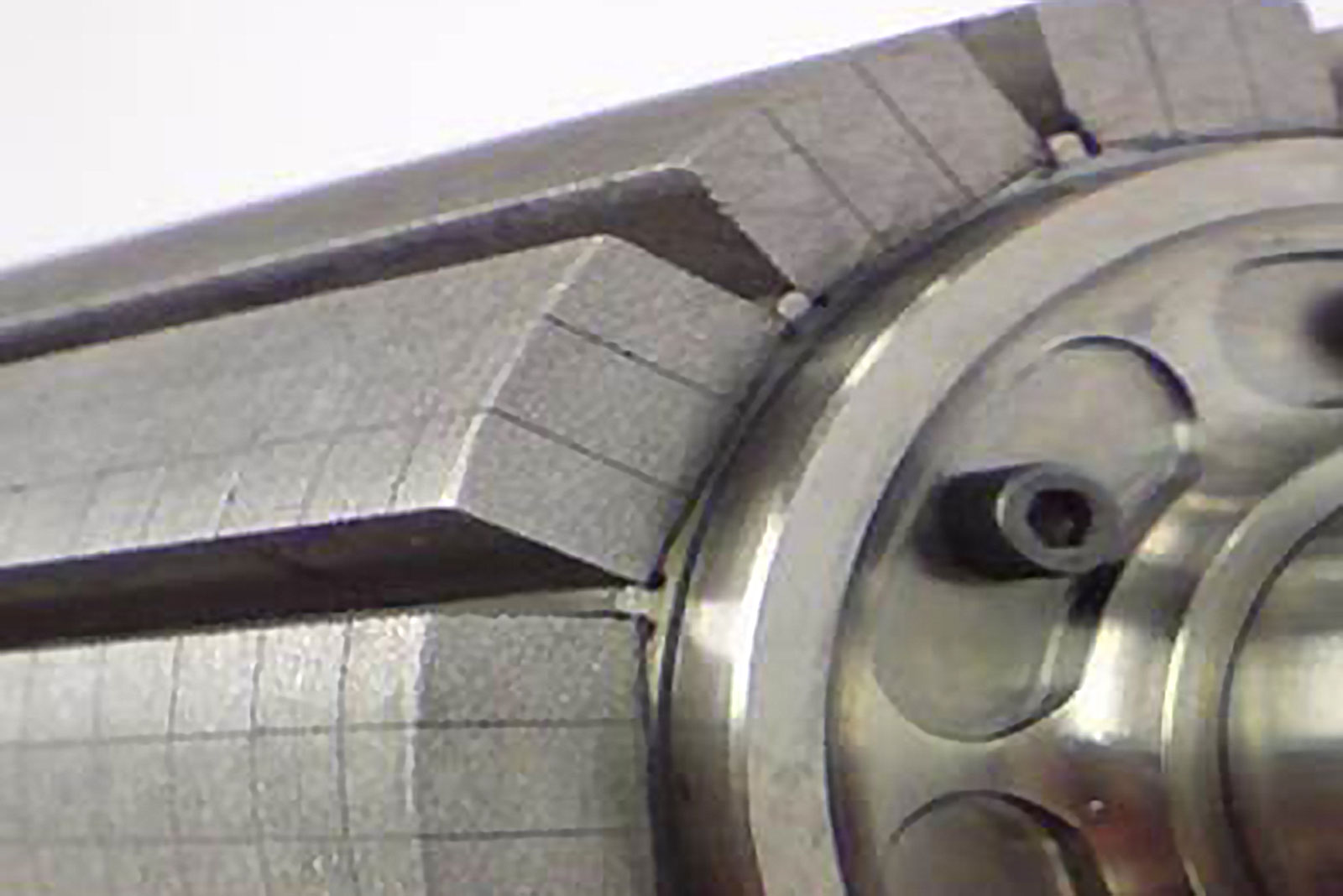

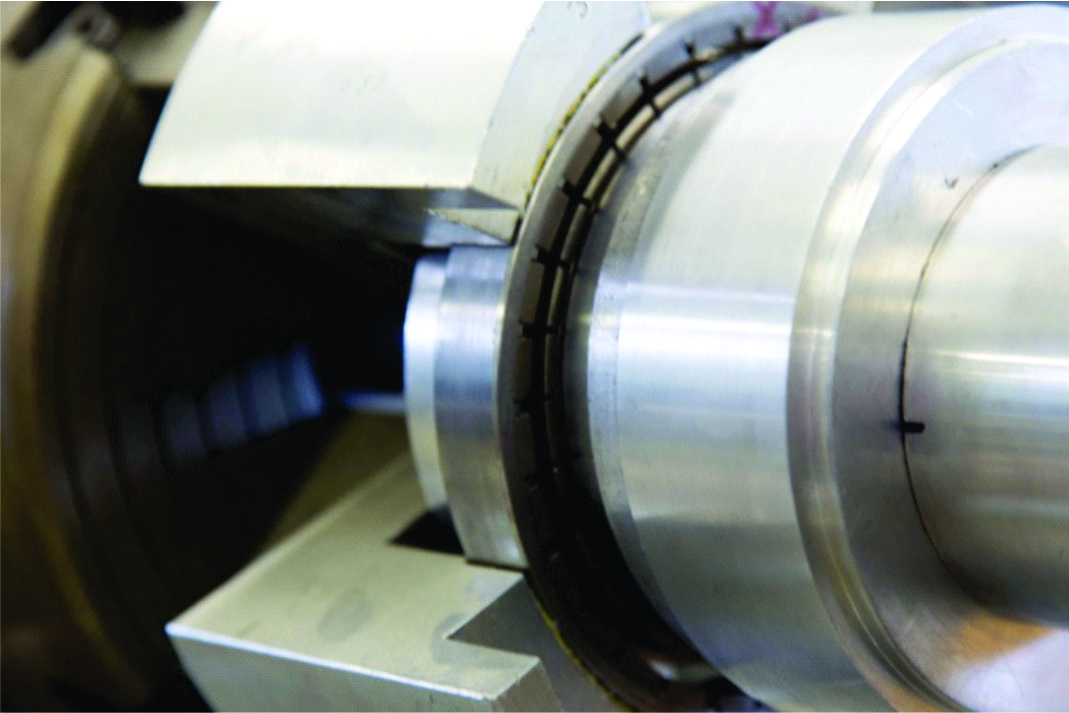

Permanent Magnet Rotors

Arnold produces high performance motor components and sub-assemblies for aerospace and defense, industrial, automotive, and motorsport applications.

Learn More -

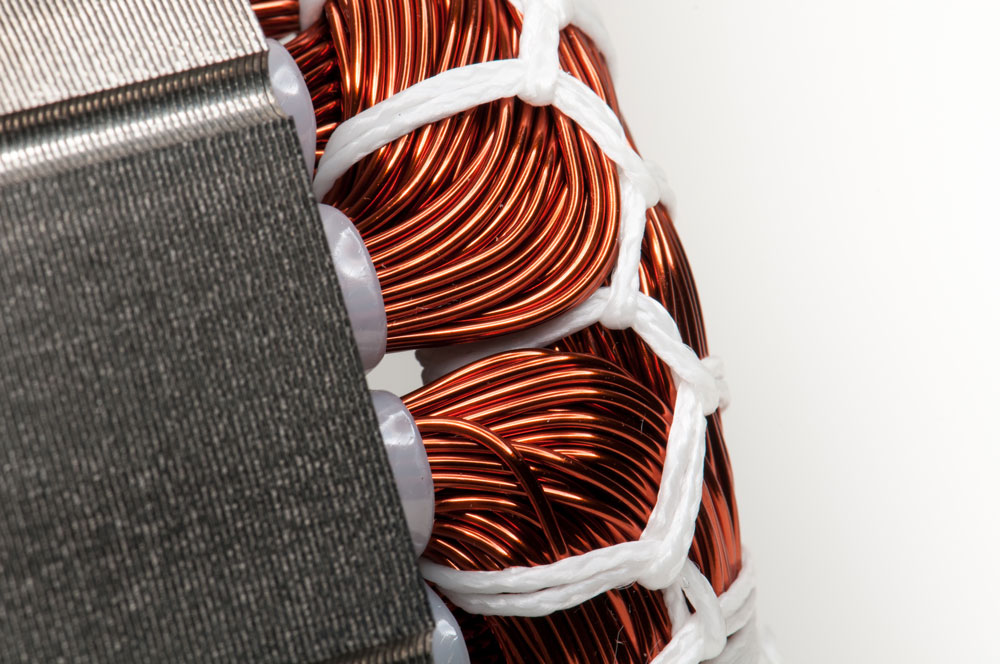

Stators and Motors

Arnold has acquired Ramco Electric Motors and now offers a variety of stator and motor production capabilities. Click the button below to visit the Ramco website. For new, custom stator projects, Arnold’s Technology Center Team is available for design engineering support and rapid prototyping.

Learn More -

Shaped Fields and Magnetic Field Technology

By managing the magnetic field distribution, Arnold’s Shaped Field Magnets provide enhanced performance and offer greater design flexibility— often at a lower cost.

Learn More

Call or message your Arnold representative today.

SERVICES

Arnold’s world-class team of Engineers, Designers, and Project Managers direct the production of products and assemblies at our facilities. You will receive outstanding support at every stage of your project, no matter what material you choose or how complex your design.

MARKETS

Our products are mission-critical to designs in many sectors, and our company has been evolving to meet emerging needs for over 100 years. By conforming to the requirements of the most demanding markets, we ensure world-class quality and service is carried through for every customer.