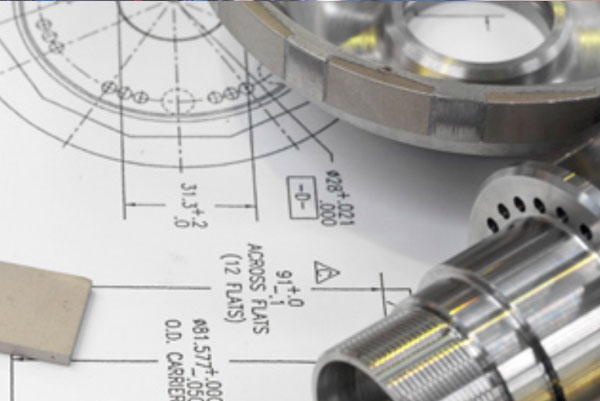

Arnold’s world-class team of Engineers, Designers, and Project Managers direct the production of products and assemblies at our facilities. You will receive outstanding support at every stage of your project, no matter what material you choose or how complex your design.

PERMANENT MAGNETS

Arnold offers a wide array of design and development services to help you overcome the obstacles and challenges of subassembly and product development. Beginning with selecting the right material, we work with you to engineer the best solution for your project and take it to completion.

PRECISION THIN METALS

In addition to providing a wide range of exotic alloys and common metals, we offer a variety of services that enable us to meet the stringent demands of our customers. We maintain precise temperatures and environmental controls for optimum accuracy in our rolling process.

- Design & Engineering

- Precision Thin Metal Prototyping

- FEA Analysis

- Rolling

- Annealing

- Slitting

- Insulated Coating

FLEXIBLE MAGNETS

Flexmag products are manufactured in state-of-the-art facilities where raw material is turned into standard and specialized compounds for profile, strip or sheet applications. We offer a full range of secondary operations, including die cuts and a variety of adhesives and vinyl backings.

ELECTROMAGNETICS

Arnold designs, builds and refurbishes electromagnet/solenoid projects of all sizes. We manufacture bobbin wound coil assemblies in large quantities, custom stator projects in small quantities, and we manufacture/refurb solenoids that weigh several tons.

MAGNETIC ASSEMBLIES

Rotor assemblies for permanent magnet motors are our specialty, but we produce a variety of magnetic assemblies, starting with simple alnico and aluminum pot magnets. We roll non-grain oriented steel for laminated stator stacks, and can produce prototypes and custom stator projects out of our Technology Center. Our engineers can work with you to create solutions that make your motor design lightweight and efficient, and help manage your costs.