Holistic solutions from rare earth supply chain stability to custom motor design optimization and assembly

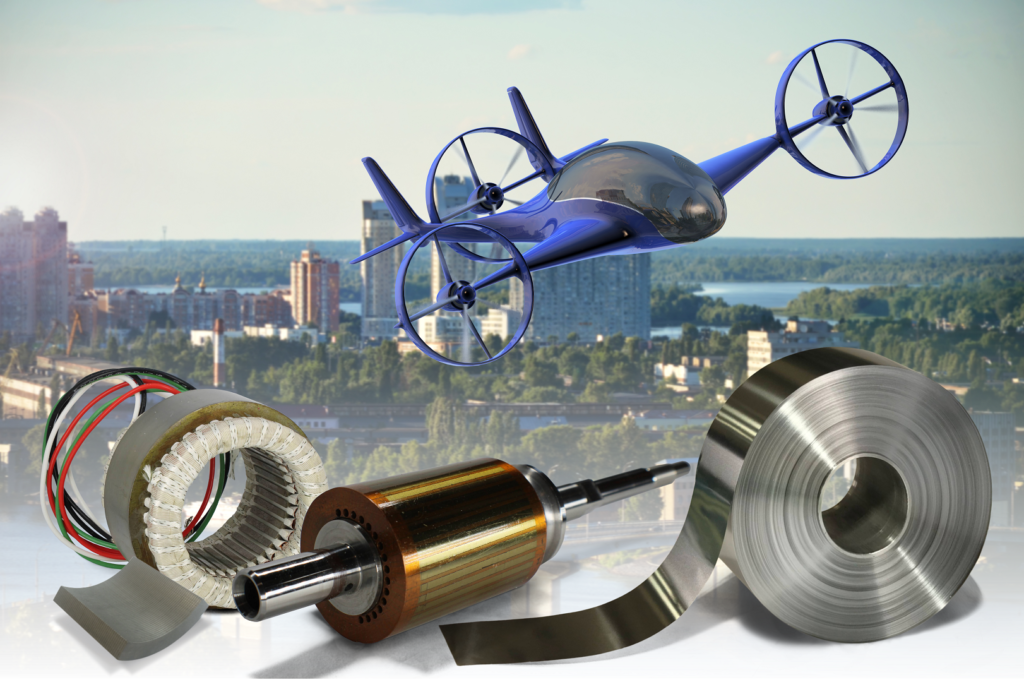

Rochester, NY: Arnold Magnetic Technologies Corporation (“Arnold”), a subsidiary of Compass Diversified (NYSE: CODI) and leading global manufacturer of high-performance magnets and more, highlights its design optimization and manufacturing capabilities for electric motors and their applications. Arnold presents customers with answers to electric transportation’s most pressing design and manufacturing challenges. One of which is electrical motors’ high-power density challenge.

Electric motors for traction drive motors typically demand higher power densities than regular induction motors used in the industrial market. This leads transportation motor designers to use a permanent magnet based topology. Permanent magnet electric motors rely on rare earth metals to generate that power. The availability of these materials relies on uninterrupted supply chains in a select few parts of the world. Arnold’s permanent magnets include RECOMA® 35E—the world’s most power-dense Samarium Cobalt (SmCo) magnet. It is specifically created for the most demanding environments, including high speed (100,000 RPM+), high temperature (above 200°C), and highly corrosive environments, as needed in the aerospace, motorsports, and industrial sectors.

Arnold offers a broad-based, ITAR & DFARS defense-compliant source of supply for Samarium Cobalt and neodymium iron boron (NdFeB or “neo”) magnets used in electric motors. Also, Arnold’s recent partnership with Cyclic Materials of Kingston, Ontario will provide another supply source for these critical resources. Arnold and Cyclic Materials are contributing to the domestic economy by creating the world’s first circular supply chain for rare earth materials through reclamation.

In applications where high power density is a must, efficiency must be maximized. Arnold’s other products include precision rolled thin and ultra-thin metals which help customers achieve efficiency gains in their motor and transformer designs. Arnold’s materials offer more efficient use of electrical steel, resulting in higher power density and energy savings. For insulation purposes, Arnold’s non-grain oriented electrical steel, Arnon®, offers the thinnest insulating layers with the lowest eddy current losses. Together, these elements maximize efficiency.

Arnold has long played a pivotal role in the electrification of transportation. Since the invention of the electric train, they’ve been innovating to bring customers the highest-grade materials and service. Today, they work with their customers to pioneer electric propulsion systems for space, air, watercraft, motorsport vehicles, and heavy equipment.

Through complete system integration, from prototype to production, Arnold’s materials can be tailored to specific application needs. Utilizing high-performance permanent magnets and manufacturing techniques, like composite encapsulation, Arnold can provide high-efficiency, lightweight designs without compromising other requirements.. Arnold’s electric rotors, stators, and motors are built to withstand the most grueling applications.

From R&D to production, Arnold’s research and development teams offer their expertise on businesses’ future electrical transportation projects. For more information on Arnold’s electric motor capabilities, visit: https://www.arnoldmagnetics.com/electric-motors/

About Arnold Magnetic Technologies

Based in Rochester, NY with an operating history of more than 125 years, Arnold is a leading global manufacturer of engineered solutions for a wide range of specialty applications and end-markets, including aerospace and defense, general industrial, motorsport, oil and gas, medical, and energy. From its Technology Center and manufacturing facilities located in the United States, the United Kingdom, Switzerland, and China, the company produces engineered magnetic assemblies in addition to high-performance permanent magnets, precision foil products, and highly loaded composites that are mission critical in motors, generators, sensors, and other systems and components. Based on its long-term relationships, the company has built a diverse and blue-chip customer base totaling more than 2,000 clients worldwide. For more information on Arnold, visit https://www.arnoldmagnetics.com.