Ultra Thin Gauge Alloy Strip and Foil

The Precision Thin Metals (PTM) division of Arnold Magnetic Technologies produces thin and ultra-thin alloys that improve the power density of motors, transformers, batteries and many other applications in automotive, aerospace, energy exploration, industrial and medical markets.

For example, our Silicon Steels improve the power density of motors and transformers, our ultra-thin Ni, Al and Cu are facilitating the development of tomorrow’s batteries, while our thin Titanium strip is both strengthening and lightening components used in the aerospace industry.

HOW THIN IS THIN?

Thinness is a relative term and we’re often asked how we categorize the end-product’s thinness or gauge. We define thin and ultra-thin this way:

Thin gauge

0.060″ to 0.0005″

1.524mm to 0.013mm

Ultra-Thin / Foil

0.00049″ to 0.000069″

0.01245mm to 0.00175mm

Arnold’s Precision Thin Metals manufacturing processes allow us to control the properties of a wide range of materials to meet your required specifications. Our metallurgists and engineers are experienced in designing solutions for your most demanding applications.

The Precision Thin Metals division is ISO 9001, AS9100, and Nadcap certified for heat treatment, demonstrating our commitment to quality processes and continuous improvement.

Arnold is your non-traditional trusted partner, registered with ITAR and can adhere to DFARS clauses.

Materials

-

Titanium Foils and Alloys

The exceptional characteristics for high overall strength, biocompatibility, corrosion resistance, and workability make titanium ideal for hundreds of applications ranging from E-beam shielding to drug delivery to aerospace surfaces and structures. Titanium sheet and foil materials are available in a number of grades.

Learn More -

Stainless Steel & Its Alloys

Excellent corrosion resistance and good workability make stainless steel the obvious choice for commercial and defense aviation devices, precision instruments and components, solar panels and other energy generation apparatus and more. It’s rolled to precise tolerances for thinness and flatness.

Learn More -

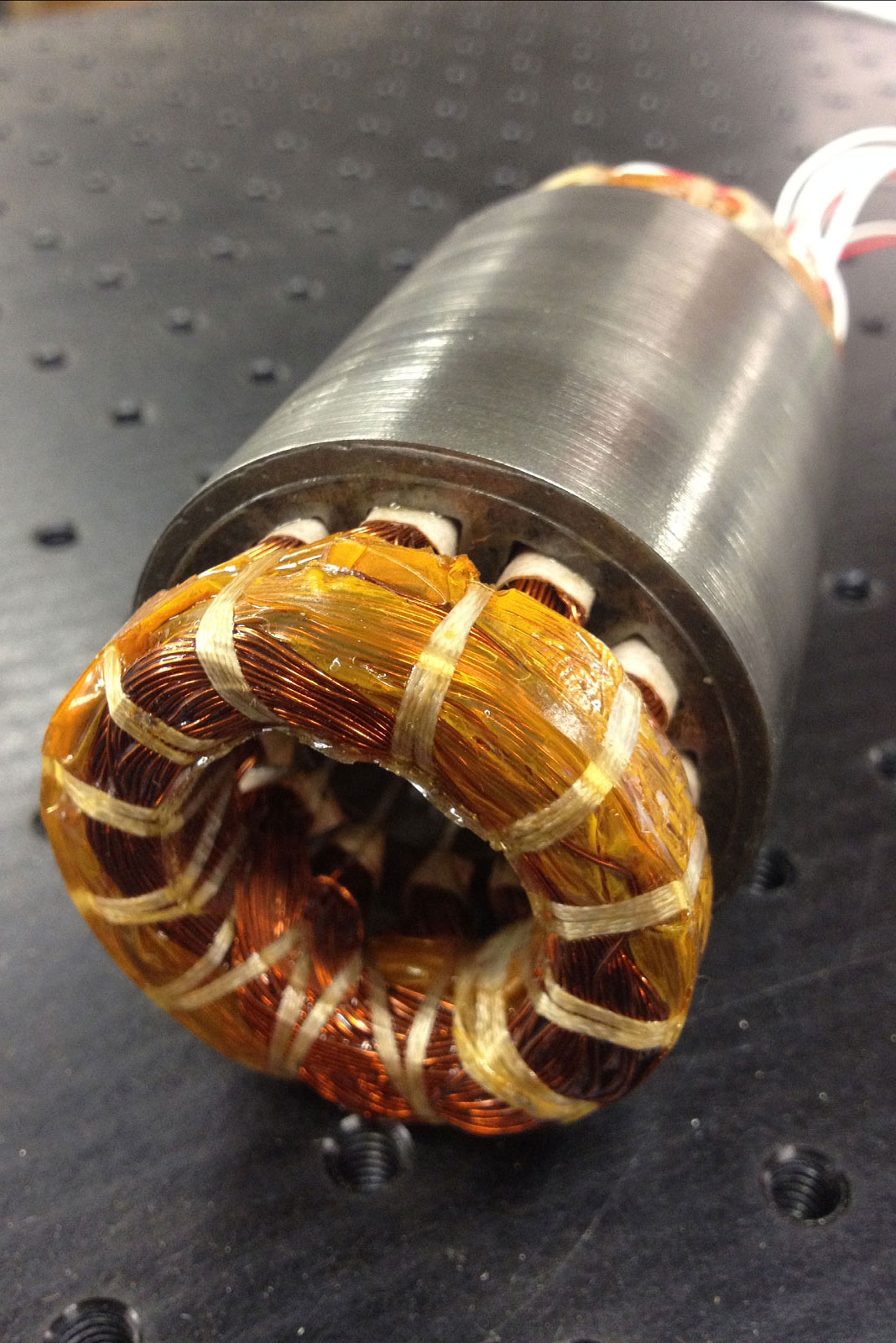

Nickel Irons & Soft Magnetics

Thin-rolled nickel-iron alloys and soft magnetic materials used for efficient energy storage and transfer. Nickel-iron alloys are characterized by relatively high permeability and low core losses. Their overall high saturation flux density means high performance energy storage and transfer over low to middle frequencies.

Learn More -

Nickel & Its Alloys

High quality grades of nickel and nickel alloys rolled and fabricated to meet the most demanding specifications. Nickel is ideal for applications ranging from rechargeable battery technologies to microphone capsules to strain gauges, instrumentation sensors, gaskets, motor valves, and other devices.

Learn More -

Inconel

Known for its strength, and high temperature and corrosion resistance, makes it an excellent material choice for many applications in the aerospace and chemical industries including: aviation thrust reversers and ductwork, industrial pressure sensors and gauges, and sodium sulfide manufacturing applications.

Learn More -

Copper & Copper Alloys

Thin-rolled copper and copper alloys serve a broad range of needs. This versatile material is used in a variety of electrical products, heat exchangers, solar collectors, piping and other applications that require strength and corrosion resistance.

Learn More -

Carbon Steel

High quality thin and ultra- thin carbon steel comes in various grades, rolled to precise tolerances for thinness and flatness. Its excellent workability makes carbon steel the obvious choice in numerous commercial, automotive and defense applications.

Learn More -

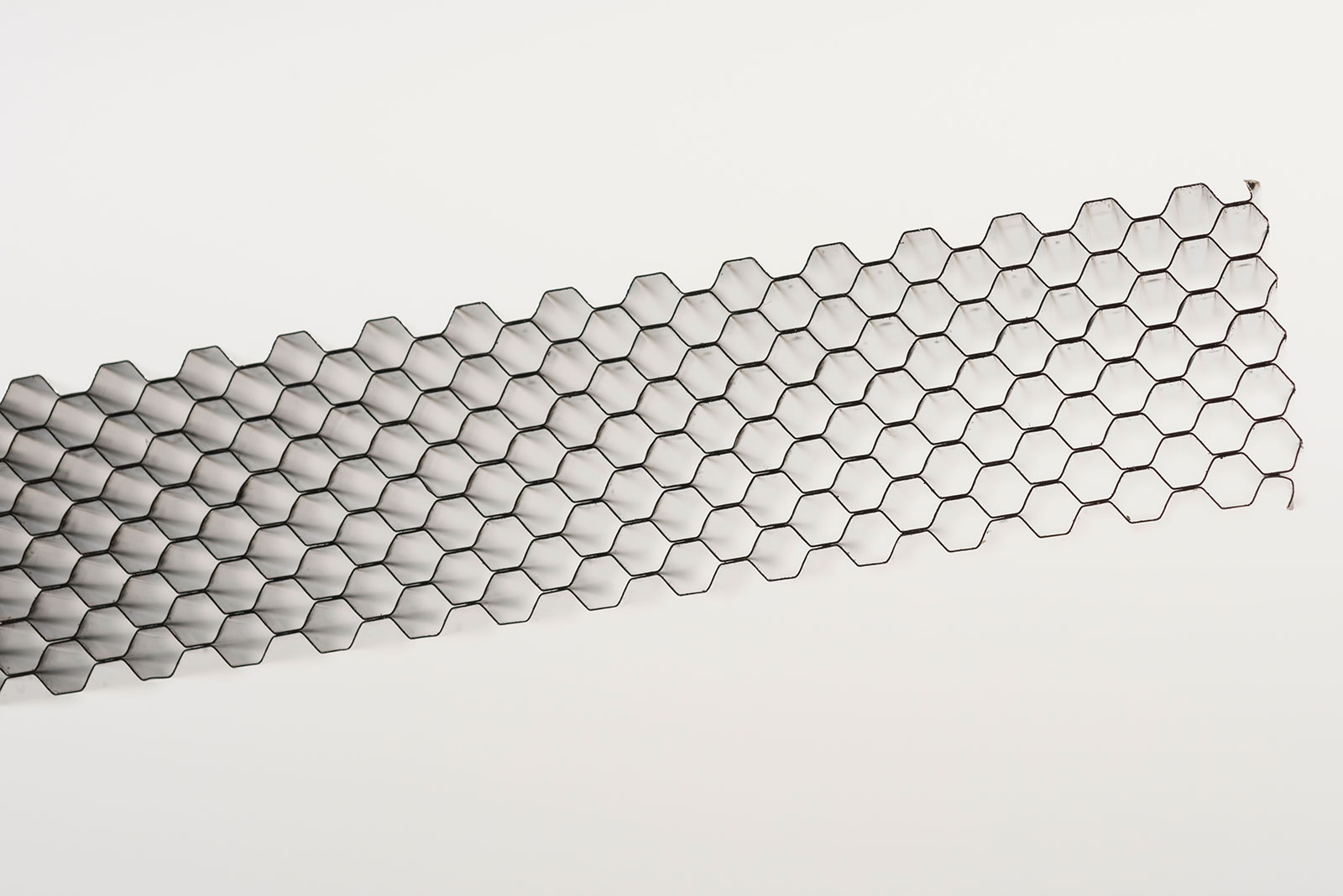

Arnon (NGOES) Electrical Steel

Arnold Magnetic Technologies Non Grain Oriented (NGOES) Electrical Steels optimized by thickness and finish to meet your most demanding needs for high speed, high efficiency motors and high efficiency transformer applications. When optimally applied, NGOES offers reduced eddy currents which translate into energy savings.

Learn More -

Aluminum & Its Alloys

Thin-rolled aluminum and aluminum alloys are versatile and lightweight and used in a variety of electrical products packaging and other applications. Aluminum is often the best solution when reduced weight, good conductivity, and high formability are desirable characteristics.

Learn More

Call or message your Arnold representative today.

SERVICES

Arnold’s world-class team of Engineers, Designers, and Project Managers direct the production of products and assemblies at our facilities. You will receive outstanding support at every stage of your project, no matter what material you choose or how complex your design.

- Design & Engineering

- Precision Thin Metal Prototyping

- FEA Analysis

- Rolling

- Annealing

- Slitting

- Insulated Coating

MARKETS

The thin and ultra-thin alloys produced by the Precision Thin Metals (PTM) business are used in a wide range of markets and applications. Most applications are geared toward enabling customers’ designs to be lighter, smaller, and more efficient. PTM materials are used extensively in: